Pile Dynamic Load Test (DLT)

SLP performs

Pile Dynamic Load Test (DLT) in accordance with ASTM D4945-00 Standard Test Method for High-Strain Dynamic Testing of Piles. In our team of experienced engineers we have a certified

EXPERT in field of the Dynamic Measurement and Analysis.

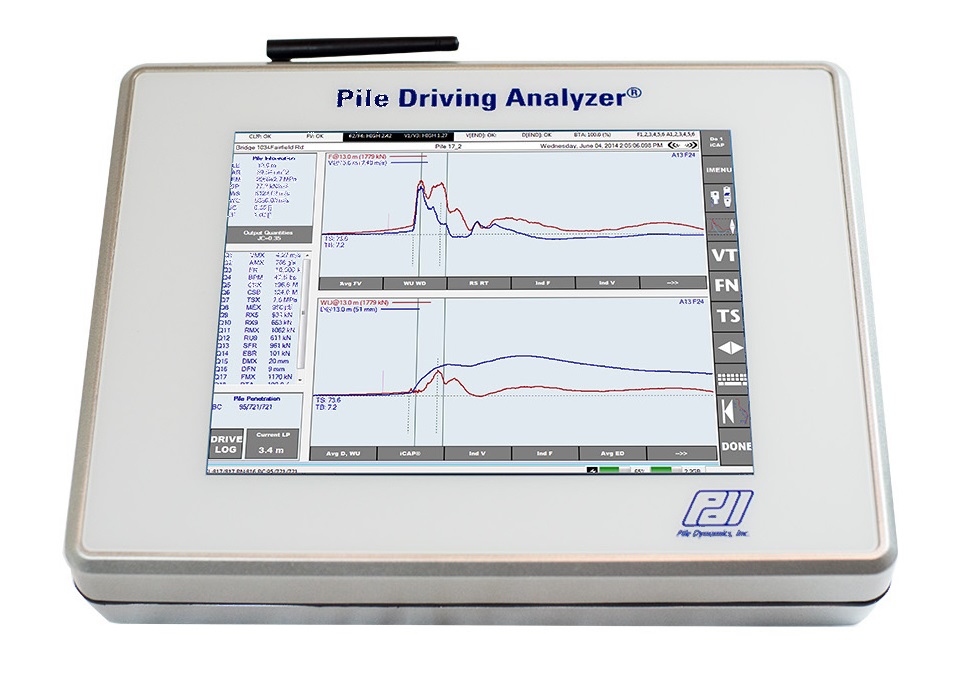

Pile Dynamic Load Test (DLT) is a fast, reliable and cost effective method of assessing pile foundation bearing capacity. SLP uses the Pile Driving Analyzer®, CAPWAP® software and Free Fall Weight Hammers of our own design from 1,6 up to 54 tons to perform the testing. SLP engineers furnish a detailed report for each Dynamic Load testing project that includes a simulated static load test in the form of a calculated load-test curve.

SLP performs

Pile Dynamic Load Test on driven piles, drilled shafts and other cast in place piles and usually conducts several tests in one single day. DLT presents an alternative to Static Load Test (SLT) and can be performed both onshore and offshore.

Pile Dynamic Load Test (DLT) involves a substantial ram mass that impacts the top of the pile and causes it to experience at least a small permanent set. Accelerometers and strain transducers attached to the pile measure force and velocity as the free fall weight hits pile top. In addition to bearing capacity, Pile Dynamic Load Testing gives information on resistance distribution (shaft resistance and end bearing) and evaluates the shape and integrity of the foundation element.

Click for:

Avaliable Free fall weight hammers list

Pile Driving Monitoring

Monitoring a driven pile installation with the Pile Driving Analyzer® reveals pile capacity at the time of driving, driving stresses, hammer performance and checks pile integrity. It can be performed by a SLP Engineer on site or via cell phone from an office, using the remote data transmission feature of the Pile Driving Analyzer® model 8g.

Pile Driving Analyzer® 8g, strain transducer and accelerometer mounted on a pile are the same as for Dynamic Load testing (DLT).

During pre-construction test programs,

Pile Driving Monitoring helps formulate driving criteria. During the installation of production piles, it assures that driving happens in accordance with the established criterion. It gives information on soil resistance at the time of monitoring and on driving performance.

Pile Driving Monitoring also reveals driving stresses, and helps to prevent pile damage. If damage is imminent, it shows an alert early enough to save the pile from complete destruction. Monitoring happens during driving in real time, without slowing down the construction. Dynamic Pile Monitoring helps achieve a safe and economical driven pile installation.

Data obtained during Pile Driving Monitoring may be used to determine static bearing capacity with iCAP® and CAPWAP® program.

SLP performs Pile Driving Monitoring in accordance With ASTM D4945-00 Standard Test Method for High-Strain Dynamic Testing of Piles.

Pile Static Load Test (SLT)

SLP has equipment to perform

Pile Static Load Test (SLT) up to 12.500 kN (cca. 1250 tons). We use five calibrated Enerpac 250 ton cilinders with 300 mm stroke, Enerpac electric pumps, Sisgeo load cell and Mitutoyo digital gauges with direct displacement reading on computer during the test.

SLP performs Pile Static Load Test (SLT) in accordance with ASTM D1143 / D1143M – 07(2013) – Standard Test Methods for Deep Foundations Under Static Axial Compressive Load.